In recent years, with the continuous upgrading of technology, the future growth trend of laser welding of plastics has gradually emerged. In the past few years, there have been no breakthroughs in some laser technologies, and the price of lasers is relatively high. Compared with traditional welding, the one-time investment is larger and may not yield benefits quickly. But now the economic advantages of laser are highlighted. Laser welding of plastics can reduce the difficulty of product design by designers.

The application methods of plastic laser welding are different from those of metal welding, including simultaneous welding and irradiation mask welding, which are briefly introduced below.

Scan welding

Scanning welding is also called quasi-synchronous welding. Scanning welding technology combines the above two welding technologies of sequential circumferential welding and synchronous welding. A reflector is used to generate a high-speed laser beam with a speed of 10 meters/second, and moves along the part to be welded, causing the entire welding part to gradually heat up and fuse together.

Quasi-synchronous welding is the most widely used. In the automotive and auto parts industry, it uses an XY high-frequency galvanometer inside. Its core is to control the collapse of plastic welding between two materials. Contour welding will produce large internal stress, which will affect the sealing of the object. Quasi-synchronous is a high-speed scanning method, and it cooperates with current control, so it can effectively eliminate internal stress.

Roll welding

Roll welding is an innovative laser plastic welding process that comes in many different forms. There are two main forms of roll welding:

The first is Globo ball welding. There is an air-cushion glass ball at the end of the laser lens. This glass ball also plays the role of focusing the laser and clamping the plastic parts. During the welding process, the Globo lens is driven by the motion platform and rolls along the welding line to complete the welding. The whole process is as simple as writing with a ballpoint pen. The Globo welding process does not require complicated upper fixtures, and only requires the production of a bottom mold to support the product. There is also a variant of the Globo ball welding process, the Roller roller welding process. The difference is that the glass ball at the end of the lens is changed into a cylindrical glass barrel to obtain a wider laser line segment. Roller roller welding is suitable for wider welding.

The second is the TwinWeld welding process. This plastic laser welding process adds a metal pressure wheel to the end of the lens. During the welding process, the pressure wheel presses the edge of the welding line for welding. The advantage of this plastic laser welding process is that the metal pressure wheel will not wear out, which is conducive to large-scale production. However, the pressure of the pressure wheel acts on the edge of the welding line, which easily generates torque and causes various welding defects. At the same time, because the lens structure is relatively complex, it causes certain difficulties in welding programming.

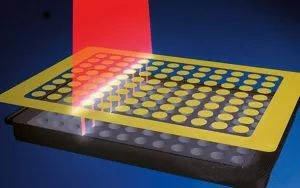

Irradiation mask welding

The laser beam is positioned through the template to melt and bond the plastic. The template only exposes a small and precise welding area on the plastic layer below. The laser beam only heats the part of the product that is not covered by the mask. High-precision welding down to 10 microns can be achieved using this technology.

Microfluidic components can be welded precisely and securely using the mask welding principle. The channel geometry remains intact, preventing melt from flowing into narrow channels of only 200 µm.

Applications of Laser Welding in the New Energy Automobile Industry