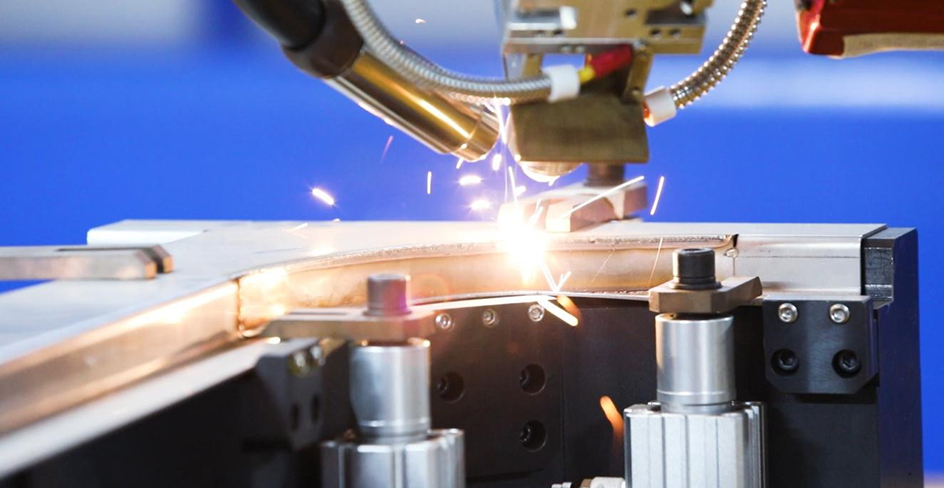

Traditional welding machines have a big problem in processing thin stainless steel sheets. Due to their small thermal conductivity and low degree of restraint, thin stainless steel sheets will form uneven stresses and strains once they are locally heated and cooled during the welding process. , the longitudinal shrinkage of the weld produces a certain pressure on the outer edge of the stainless steel sheet. Once the pressure of the traditional welding machine is too high, it will cause wave-like deformation of the workpiece, which not only affects the appearance but also affects the quality of the workpiece. In addition, there will be Problems with over-burning and burn-through. The emergence of fiber laser welding machines solves this problem. Laser welding uses high-energy laser pulses to locally heat materials in a small area.

Compared with other welding machines, the advantage of metal laser welding machine for welding metal is that it has a wide range of application. It can be widely used in welding stainless steel, metal, alloy and other same materials, and can also achieve welding of different materials; then laser welding machine is very useful in welding super What are the process advantages of thin materials?

The process advantages of laser welding machine in welding ultra-thin materials:

1. Laser welding machines are easy to cooperate with computer numerical control systems or manipulators and robots to achieve automatic welding and improve production efficiency.

2. Laser processing and welding is non-contact processing, and there are no problems such as tool loss and tool replacement. The energy of the laser beam is adjustable, the moving speed is adjustable, and it can be used for various welding processes.

3. Laser welding can be controlled by a computer. It has fast welding speed and high efficiency, and can easily weld any complex shape.

4. The welding process does not pollute the environment. It can be welded directly in the air and the process is simple.

5. The welding spots are small, the welding seams are narrow, neat and beautiful, and no treatment is required or only simple treatment procedures are required after welding.

6. Because the beam is easy to transmit and control, and there is no need to frequently replace the welding torch and nozzle, which significantly reduces the downtime auxiliary time, the load factor and production efficiency are both high.

7. It is easy to realize automation and can effectively control the beam intensity and fine positioning.

The above are the process advantages of laser welding machines in welding ultra-thin materials. Positive defocus is suitable for laser welding of ultra-thin plate materials. Under the same defocus amount, the weld surface obtained by positive defocus laser welding is better than that of negative defocus. It should be smooth and beautiful. For laser welding of ultra-thin stainless steel materials, because the material is very thin, it is easy to vaporize and perforate. The key to obtaining a continuous weld without burn-through is precise control of parameters.

Should Laser Welding Machines Choose Pulse Welding or Continuous Welding?

What You Need to Know About Handheld Fiber Laser Welding Machines?