The sensor integrates sensing chip, communication chip, microprocessor, driver, and software algorithm into one, and has functions such as information collection, information processing, information exchange, and information storage.

With the development of laser technology and automation technology and the mature application of sensor production processes, domestic companies that mainly master the core technology of laser welding play a major role in further solving the problems of low accuracy and poor stability of traditional sensor processes.

Advantages of laser welding

Laser welding has many benefits compared to traditional arc welding processes:

1. Selective energy application in a small area: reduce thermal stress and heat-affected zone, extremely low distortion.

2. Narrow joints and smooth surfaces: reduce or even eliminate reprocessing.

3. Combination of high strength and low welding volume: the welded workpiece can undergo bending or hydroforming.

4. Easy to integrate: can be combined with other production operations, such as alignment or bending.

5. Only one side of the seam needs to be closed.

6. High process speed shortens processing time.

7. Especially suitable for automation technology.

8. Good program control: Machine tool control and sensor systems detect process parameters and ensure quality.

9. The laser beam can produce welding spots without touching the surface of the workpiece or exerting force on the workpiece.

Sensor laser welding process

In the current rapidly developing Chinese industrial market, the demand for sensors has changed from original supporting equipment to rigid demand. Especially on May 10 this year, the first batch of key special projects in the “14th Five-Year Plan” national key R&D plan were released, and “smart sensors” were on the list. In the future, the basic and cutting-edge technologies of intelligent sensing, key technologies of sensor sensitive components, and key technologies of sensor sensitive components will be systematically laid out for the industry. Intelligent sensors and systems and sensor R&D support platforms integrate intelligent sensor design, manufacturing, packaging testing and application demonstration links to lead the sustainable and large-scale development of the sensor industry.

As high-precision detection instruments, sensors have extremely stringent requirements, especially in military, aviation, and aerospace applications. In order to develop and produce high-accuracy and high-stability sensors, a complete and effective manufacturing process is essential. Why do you say that?

The main reason is that sensors such as pressure sensors, Hall sensors, photoelectric sensors, temperature sensors, etc. have sensitive components and integrated circuits inside, which are filled with inert gas or evacuated and isolated from the outside world. The production process has pressure and air tightness requirements. , which has very high requirements on welding strength, air leakage rate and welding quality. In particular, it requires small deformation during the welding process and no damage to internal components and microcircuit.

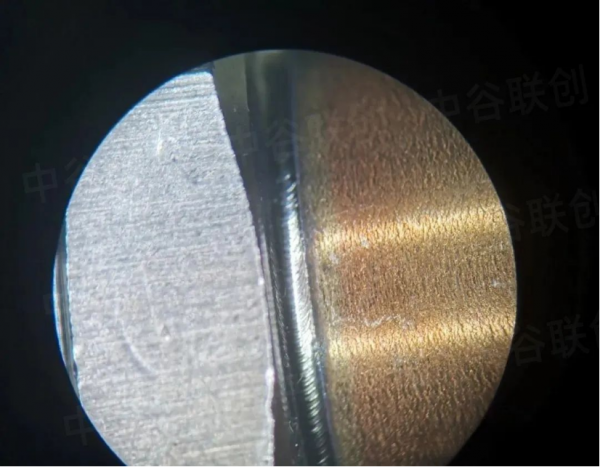

Laser welding uses laser as the welding heat source, which has the advantages of high energy density, concentrated heating, fast welding speed and small welding deformation. Since the housings of many sensors currently use stainless steel, titanium alloys, and a small amount of alloy materials and aluminum alloys, laser welding, with its unique advantages, is particularly suitable for use in sensor sealing welding.

Platform Laser Weling Machine 3 Axis Automatic Precision Riselaser RL-FPE Metal Aluminum

Fiber Laser Source Jpt Mopa Parts Of Laser Marking Machine Riselaser RL-MOPA Equipment 20W 60W 120W

The difference between laser welding machine and laser cutting machine