Under the macro background of continuous advancement of intelligent manufacturing technology and increasingly in-depth global carbon reduction and emission reduction, how to further reduce product manufacturing costs, improve product quality and functions, meet green manufacturing requirements, and gain comprehensive advantages in market competition is a must for tire manufacturing companies. Unsolved problem.

With the development of the times, the tire industry has higher and higher requirements for tire quality and function. It is paying more and more attention to the cost control and environmental protection of the tire manufacturing process using advanced manufacturing technology. It is also increasingly demanding that products meet market demand. high. At present, most tire manufacturing companies are planning to build unmanned factories, using advanced low-carbon and low-consumption manufacturing processes and tire full life cycle traceability management systems based on network cloud platforms, in order to better meet the new needs of tire users and provide tires with Bring value to manufacturing companies and users.

The use of laser technology can effectively reduce the cost of the tire manufacturing process, reduce carbon dioxide greenhouse gas emissions, and help tire companies meet the market demand for high-quality, high-performance, and multi-functional tires.

1. Tire mold laser cleaning

Laser cleaning of tire molds requires no consumables and does not cause any damage to the mold. Compared with traditional sand washing and dry ice cleaning, it consumes less energy, has less carbon emissions, and has lower noise. It can clean all-steel and semi-steel tire molds, and is especially suitable for cleaning spring sleeve molds that cannot be sand washed.

2. Laser cleaning of tire inner wall

As the requirements for automobile driving safety continue to increase and the demand for silent tires for new energy vehicles continues to rise, high-end tires such as self-repairing tires and silent tires are gradually becoming the first choice for automobile accessories. Domestic and foreign tire companies regard the production of high-end tires as their priority development direction. There are many technical means to realize tire self-repair and silence. Currently, the main method is to coat the inner wall of the tire with a soft solid gel polymer composite material to achieve explosion-proof, puncture-proof, and leak-proof functions. At the same time, a layer of leak-proof rubber is pasted on the surface. Polyurethane sponge achieves sound insulation and heat insulation, and absorbs cavity noise for a mute effect.

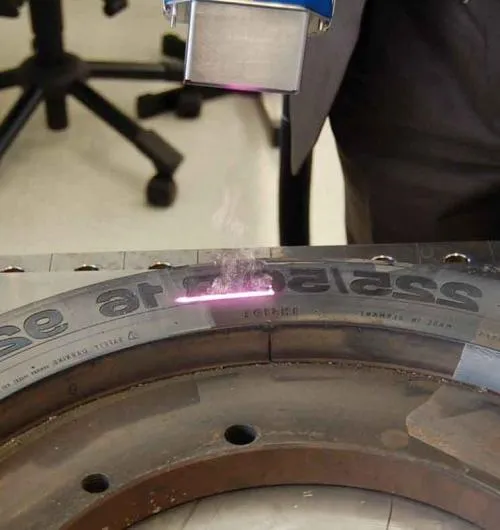

3. Tire laser coding

Laser coding is used to code the side of the finished tire instead of the traditional movable type block printing process, delaying the formation of the sidewall information text pattern until subsequent inspection and shipping processes. Laser coding has the following advantages: avoid batch losses of finished products caused by using the wrong type blocks; avoid downtime losses caused by frequent changes of week numbers; effectively improve the appearance quality of products and eliminate “flash” caused by gaps in the type blocks; barcode or two-dimensional Code marking makes product life cycle management more comprehensive and faster; tire sales can be flexibly adjusted according to order needs, reducing inventory and capital backlog.

What are the impacts of UV laser marking machines in the industrial field?

What are the impacts of UV laser marking machines in the industrial field?

What benefits does laser equipment bring to the electronic industry?